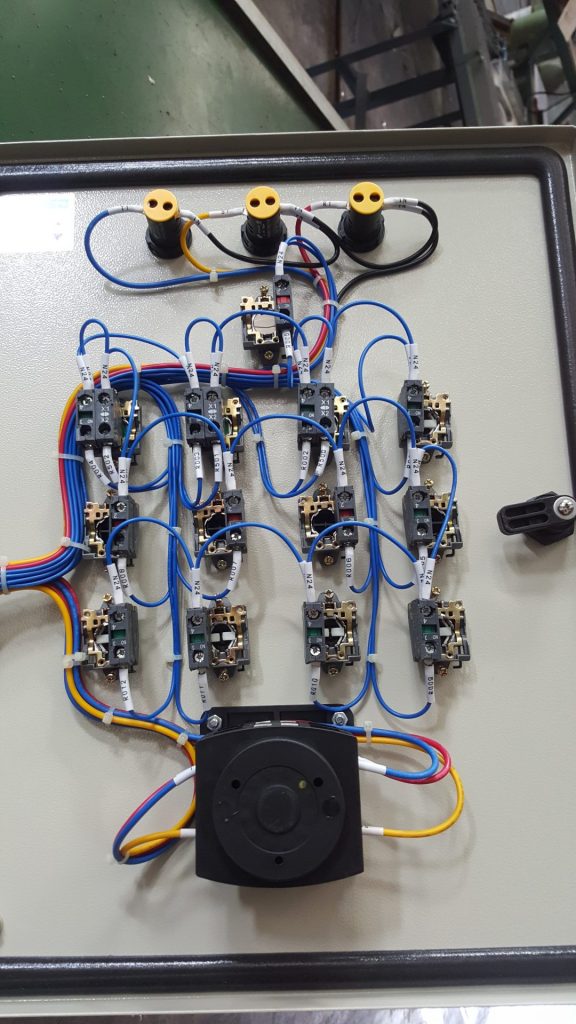

For this project we made a control panel for our end user. They can control all the operation of the tealight candle conveyor using this panel. This panel is only using push buttons, selector switch and a Keyence PLC. Image below shows the layout design of the panel.

All the push buttons, pilot lamp, selector switch are labelled nicely. With correct labeling, it is easier for us to troubleshoot, tracing problem or change anything in future.

Using the Keyence PLC, we control the conveyor with contactors and overload relays for safety. There is a omron timer to set the wax dispensing time to the metal tealight cup.

We also using a Delta servo motor & drive to dispense the tealight candle metal cup. We need to dispense accurate amount of cup at specified time, so a servo motor is used instead of a conventional motor. Every time the servo motor will dispense 2 rows of 20 units tealight cup and there is a pusher to push the cup to the other conveyor for wax dispensing. Then the candle will go into cooling and packing process afterwards.

-Keyence PLC

-Delta Servo Motor

-Single Axis Control